Welcome to our comprehensive article on 3D Modelling & Printing Using AutoFusion 360 and FlashPrint 5! In this guide, we will take you through the step-by-step process of designing the model using Auto Fusion 360, exporting the 3D model to slicing software, and finally slicing and printing the model using Flashprint 5 software. We will also provide insights on printing with PLA White filament using a Flashforge 3D printer. Whether you're a beginner or an experienced designer, this article will help you create stunning 3D models with ease. So let's dive in and explore the exciting world of SCARA robot modelling together!

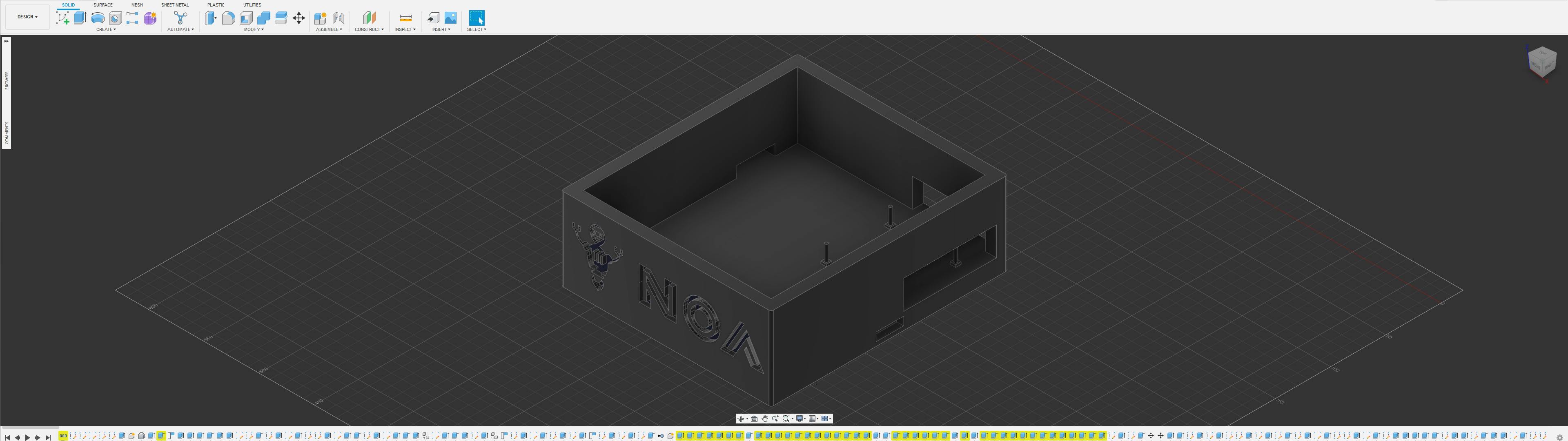

How to design in Auto Fusion 360

Designing in Auto Fusion 360 is an exciting and creative process that allows you to bring your ideas to life. Whether you are a beginner or an experienced designer, Fusion 360 offers a user-friendly interface and powerful tools that make the design process seamless. To get started, simply open the software and select the appropriate workspace for your project. From there, you can begin creating sketches, adding dimensions, and refining your design until it meets your specifications.

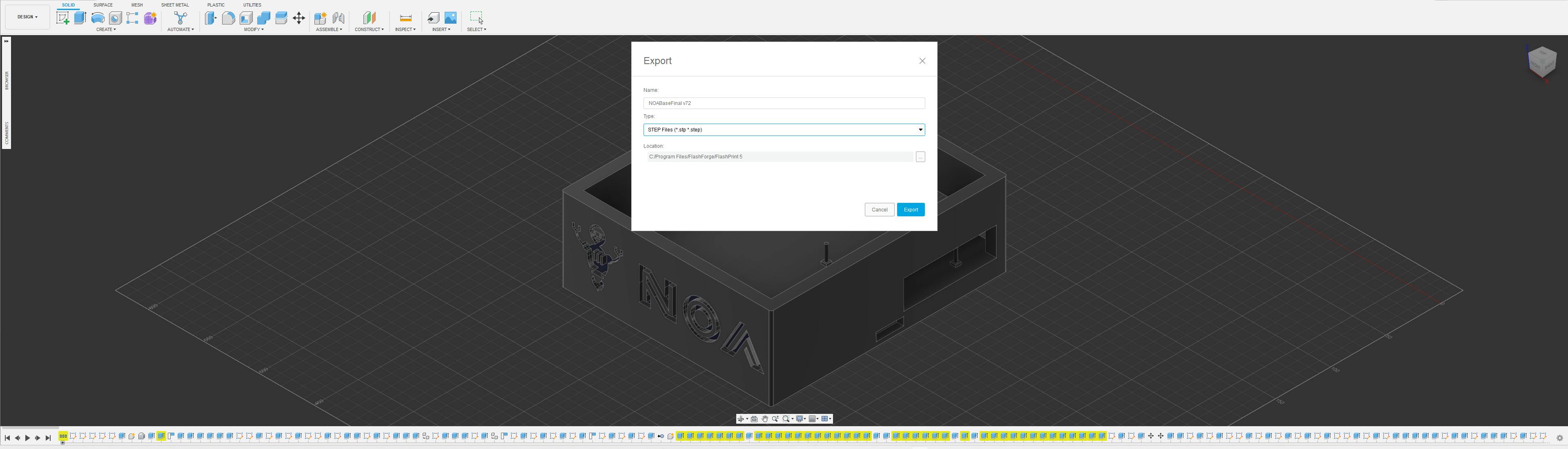

Exporting 3D Model to Slicing Software

One of the great features of Auto Fusion 360 is its ability to export 3D models to slicing software. Slicing software takes your 3D model and prepares it for printing by dividing it into layers and generating the necessary instructions for the printer. To export your model, go to the "File" menu and select "Export". Choose the file format that is compatible with your slicing software, such as STL or OBJ. Once exported, you can import the file into your preferred slicing software and make any necessary adjustments before sending it to the printer.

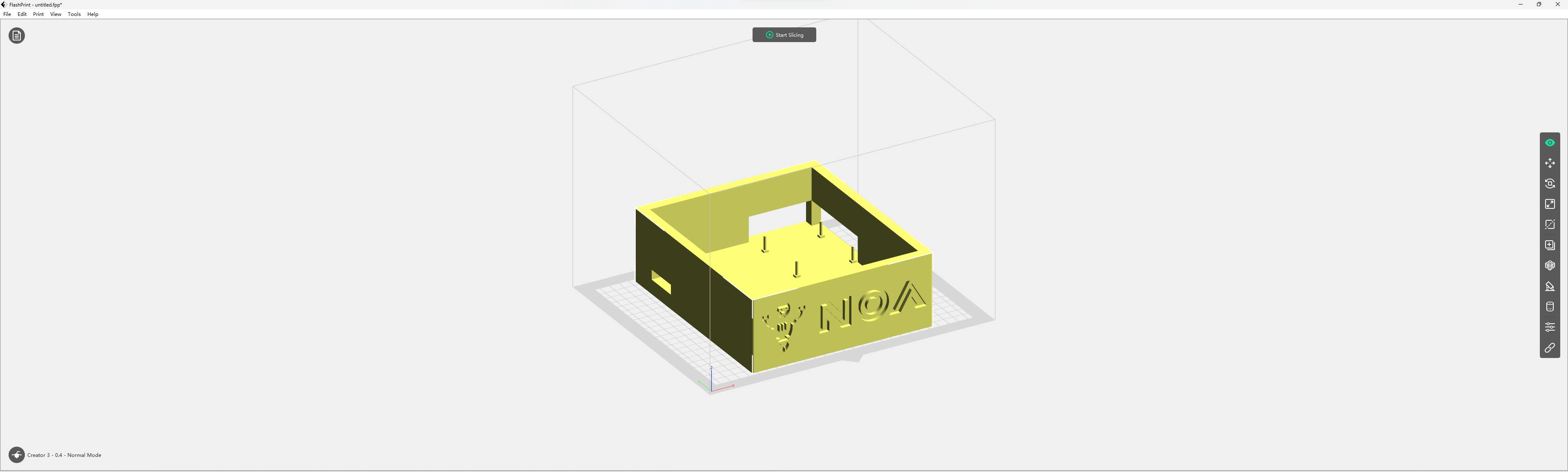

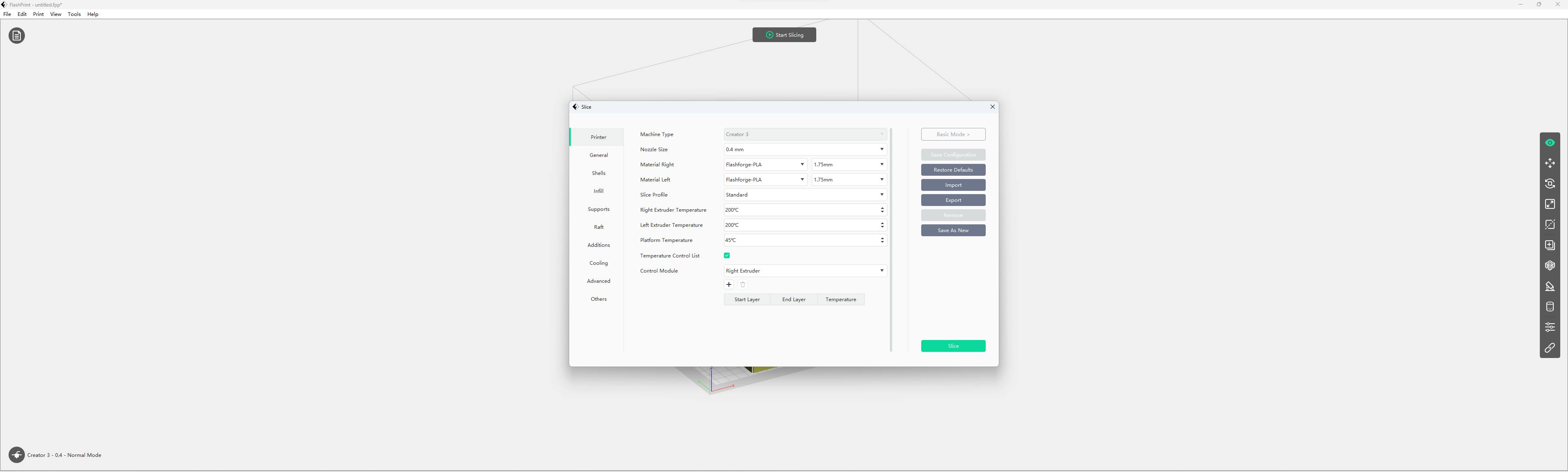

Slicing 3D Model with Flashprint 5 Software

After designing your 3D model in Auto Fusion 360, the next step is to export it to slicing software. Slicing software is a crucial tool that prepares your model for 3D printing by converting it into a series of thin layers. Slicing software acts as an intermediary between your design and the 3D printer. It allows you to adjust various settings like layer height, print speed, and support structures before sending the sliced file to the printer. One popular slicing software is Flashprint 5, which offers a user-friendly interface and advanced features for optimal printing results. Simply open Flashprint 5 and import your exported model using the "Import" function.

Once you have successfully imported your 3D model into Flashprint 5, you can start preparing it for printing. The slicing software provides options to customize settings according to your preferences and requirements. You can adjust parameters like infill density, print orientation, and support structures based on the complexity of your design. Additionally, Flashprint 5 allows you to preview each layer of the sliced model before printing, ensuring that everything looks as intended. Once satisfied with the settings and preview, save the sliced file in a compatible format (such as .gx) ready for printing on a Flashforge 3D printer.

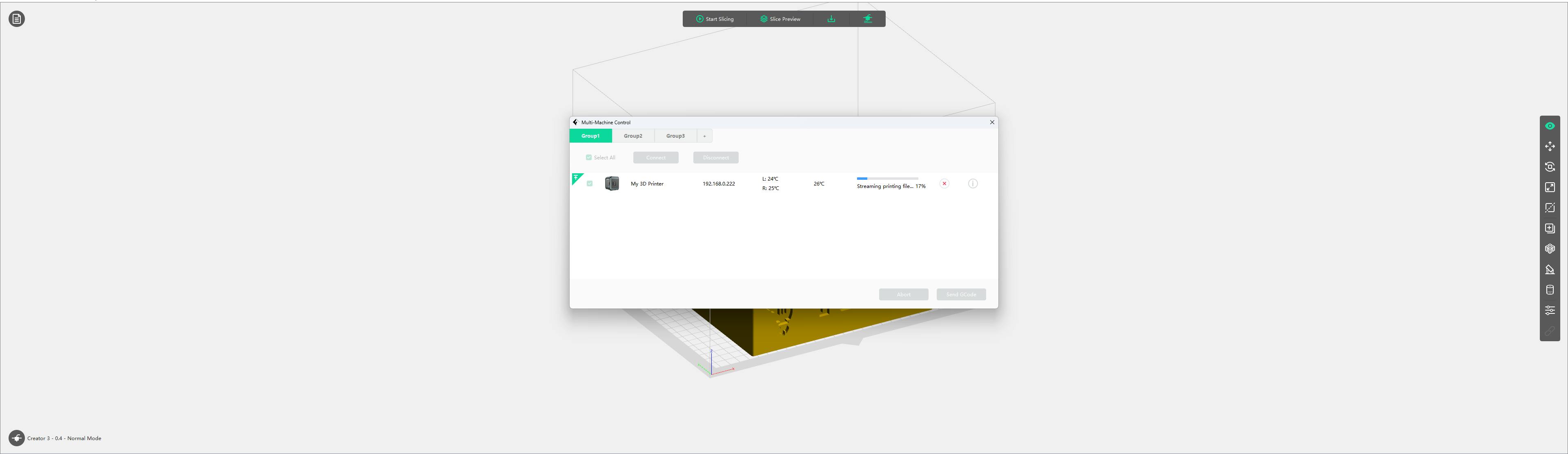

Printing Using Flashforge Creator 3 3D Printer

After slicing your model in Flashprint 5, you are ready to send it to your Flashforge 3D printer.

Make sure to load PLA White filament into the printer's extruder before starting the print job. Once everything is set up, simply click on the "Print" button in Flashprint 5, and watch as your design comes to life layer by layer. It's truly fascinating to see how a digital creation transforms into a physical object right before your eyes!

Final Product

If you will like to know how the engraving was done, stay tuned for the next article, there you will learn how it was done and you can also be a pro at this.